Hand Engraved Monogramming:

The Crystal Shoppe was opened in 1954 due to the skill and artistry of Gladys Payne, a glass artist who had learned her craft in the glass factories that abounded in West Virginia at the time. Her skill was etching glass by using a revolving stone wheel - and the current Crystal Shoppe artists still employ this method of hand-cutting initials, names, monograms and designs into glass and crystal giftware. The glass is held, upside down, against the rotating wheel and gentle pressure is applied to create the required patterns, with a small hose dripping water over the work area to keep the glass lubricated: nothing has changed in nearly 100 years of production!

Deep-etched Engraving:

These two terms are used interchangeably to describe the process of etching letters and designs into glass. The required wording or logo or design is created on a computer program and printed onto a sheet of vellum paper (not unlike tracing paper); this is then exposed onto a film and developed under ultra-violet light. The resulting film is washed out using a high-pressure water hose and then dried, before being applied to the item in question. After the film has been taped (to avoid over blast) it is placed into the blast cabinet where it is held under a nozzle that shoots sand at it, etching into the glass where it is not protected by the film. The result is a beautifully etched gift!

Opalescent Ornaments:

Also known as making lemonade, we discovered this range of blown glass ornaments when covering up a mistake (we do, occasionally, make one) - by etching the surface of the ornament everywhere except the desired monogram, name or design, we create a completely new 'look' for your ornaments, with the exposed area reflecting the beauty of the iridescence of the glass.

Made from sheet plate glass and cut by lasers into defined shapes, beveled glass ornaments are more sturdy than their blown glass counterparts and allow for more detailed and lengthier engraving options. Available in a host of designs, we offer circle, oval, teardrop, star, heart & house shaped ornaments.

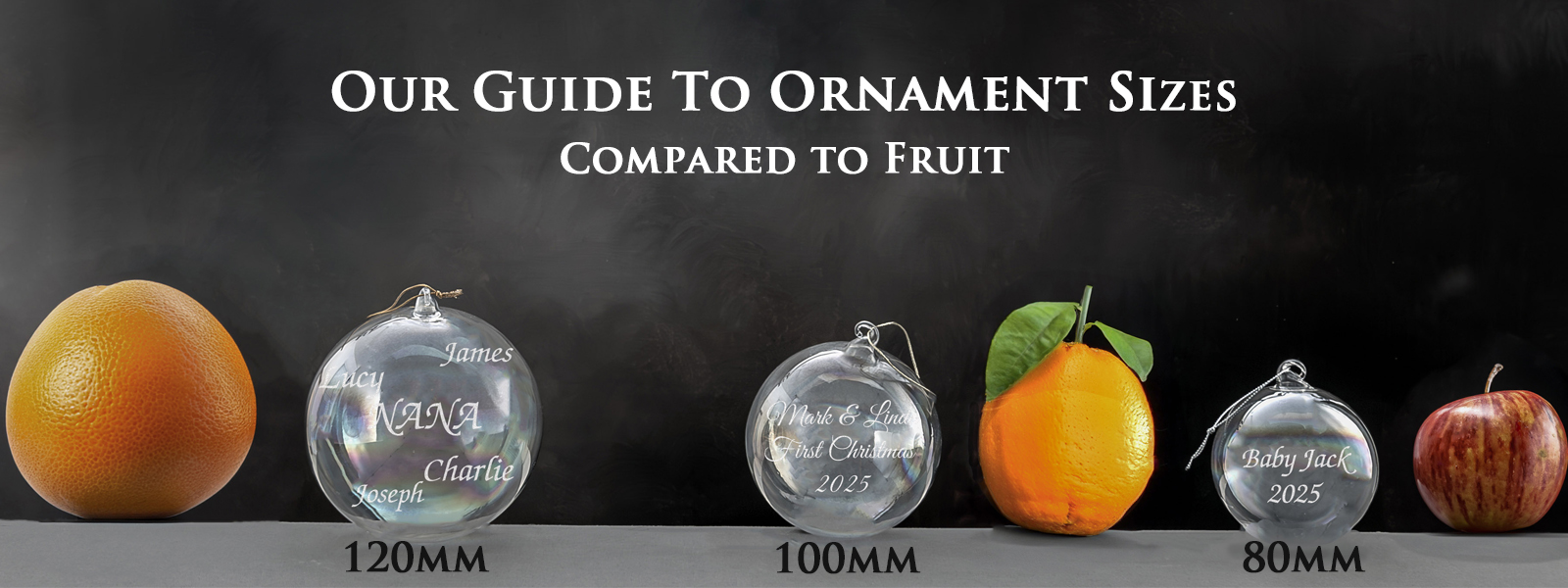

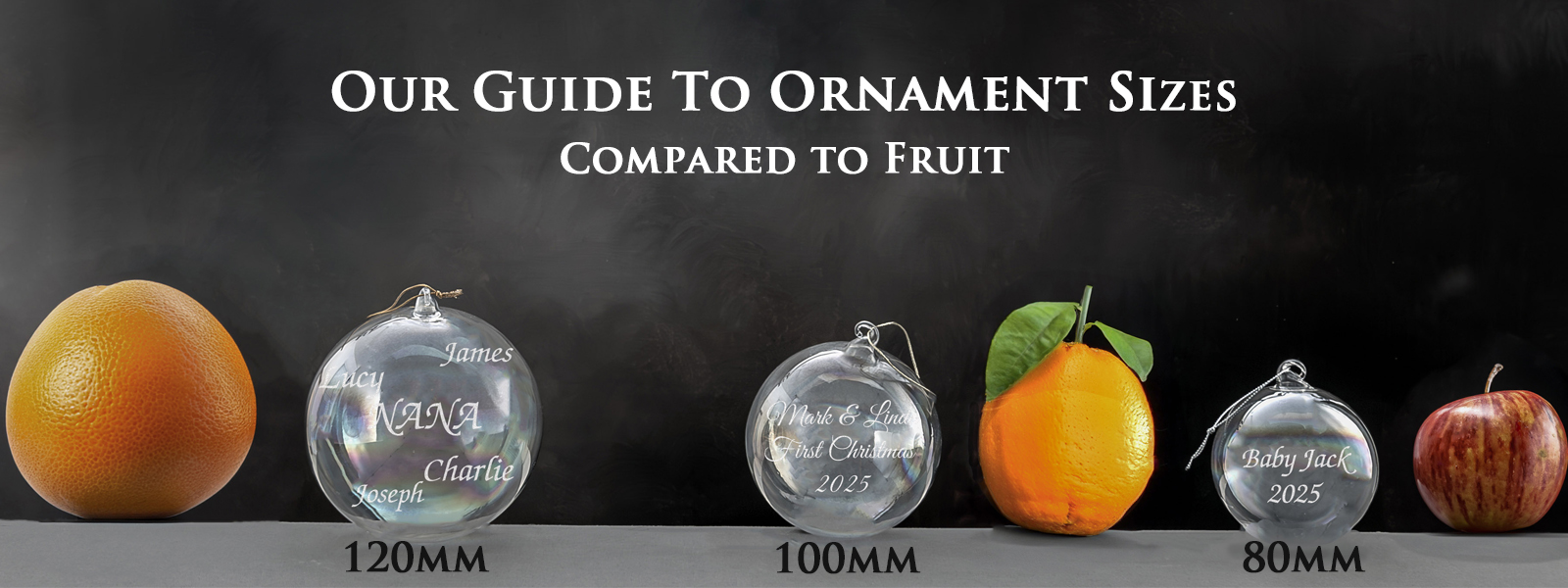

The terms 'mouth blown' & 'hand blown' are used interchangeably to describe this process, one in which the molten glass is blown into a mould and then rapidly cooled to retain the shape - in the case of the blown glass ornaments we offer, this could be spherical, in different dimensions, teardrop, heart, star, disc or other exotic shape that appeals to our artists (see 'balloon' & 'olive'!). Blown glass ornaments are, by definition, extremely delicate and the fact that our glass artists can etch a name into them using a stone wheel remains one of the wonders of the modern world.

The term 'lead crystal' has become something of a no-no when referencing crystal products. Undeterred, the industry sprung into action and developed 'lead-free crystal' and 'optic crystal', the latter implying a level of purity and quality suitable for use in telescopes, microscopes, binoculars and other optical instruments that require precision and clarity. The ornament industry saw this as an opportunity to replce the reviled lead crystal range with better-looking, safer and highly engraveable optic crystal ornaments.

We offer a line of porcelain ornaments, made from a ceramic material. Confused? We are too. So, to dictionary.com: Porcelain: a strong, vitreous, translucent ceramic material, biscuit-fired at a low temperature, the glaze then fired at a very high temperature

Ceramic: of or relating to products made from clay and similar materials

Got it? Good. In any event, this substrate offers a hardier, less fragile ornament surface, suitable for our monogramming and design work.